Reduce workplace injuries with our forklift training course

Forklifts are a common feature of many worksites. They enable employees to transport large and heavy materials quickly and easily. But while this piece of machinery is essential to the productivity and efficiency of many workplaces, some don’t have the safety policies or forklift training in place to identify the most common forklift safety hazards and prevent injuries and forklift accidents.

At FFVA Mutual, we provide policyholders with a comprehensive forklift safety training course – our forklift train-the-trainer program – to help employers better understand the relevant site-specific and equipment-specific safety hazards and implement workplace safety policies that keep employees out of harm’s way.

Common safety hazards associated with forklifts

Forklift accidents can be extremely costly for employers. Not only is there risk of serious injury to both the forklift operator and any employees working in the near vicinity of a forklift in motion, but there is also the chance of extensive property and inventory damage.

Here are some of the most common forklift safety hazards:

- Turnover: A loaded forklift’s center of gravity is much higher than when it’s not loaded, and that can create serious risk if not handled properly. If operators don’t take additional precautions while the forklift is loaded and in motion, they could tip the forklift over, causing serious injury to themselves or those around them.

- Abrupt stopping: Loaded forklifts are heavy, and operators sometimes find it difficult to stop without slipping and causing accidents, injury or damage to surrounding workers/property. Even if they do stop successfully, those sudden maneuvers can sometimes cause materials to slide or fall off completely, injuring workers nearby.

- Visibility limitations: Forklift operators have numerous blind spots that make it difficult for them to spot possible hazards in their surrounding area. Compounding this problem, many workers aren’t aware of the blind spots on forklifts, so they might inadvertently put themselves at risk by standing too close to a loaded forklift in motion.

Forklift injury prevention strategies

Many forklift-related injuries are caused by employee negligence. While inexperience is certainly a risk factor, even an experienced forklift operator sometimes looks for shortcuts, which can put them and their co-workers at risk.

For that reason, one of the most effective ways to prevent forklift-related injuries is to regularly train employees on best practices to ensure they are doing everything they can to stay safe on the job. OSHA typically requires forklift operators to receive training once every three years, though depending on the complexity of the jobsite, employers may request more frequent trainings.

In addition to regular training, some of the simplest and most effective safety techniques every worker can incorporate into their day-to-day forklift operation include:

- Staying focused at all times, whether operating forklifts or working nearby.

- Practice good fall protection by wearing a seatbelt and avoiding jumping if the vehicle starts tipping.

- Not using listening devices or cell phones while operating forklifts.

- Understanding the capacity of the lift truck and never overloading it with heavy equipment.

- Driving slowly and in a controlled manner, usually no faster than a brisk walk.

- Stopping and using your horn whenever you are passing through intersections or blind spots.

It’s important for employers to appoint a designated point-person to oversee their forklift safety program and ensure all of the above safety measures are taken every day. This should be a person with extensive forklift operation experience who also has the communication skills to convey problems and other points of concern to senior management. This person should also be responsible for daily inspections of all vehicles, ensuring all equipment is both safe and compliant.

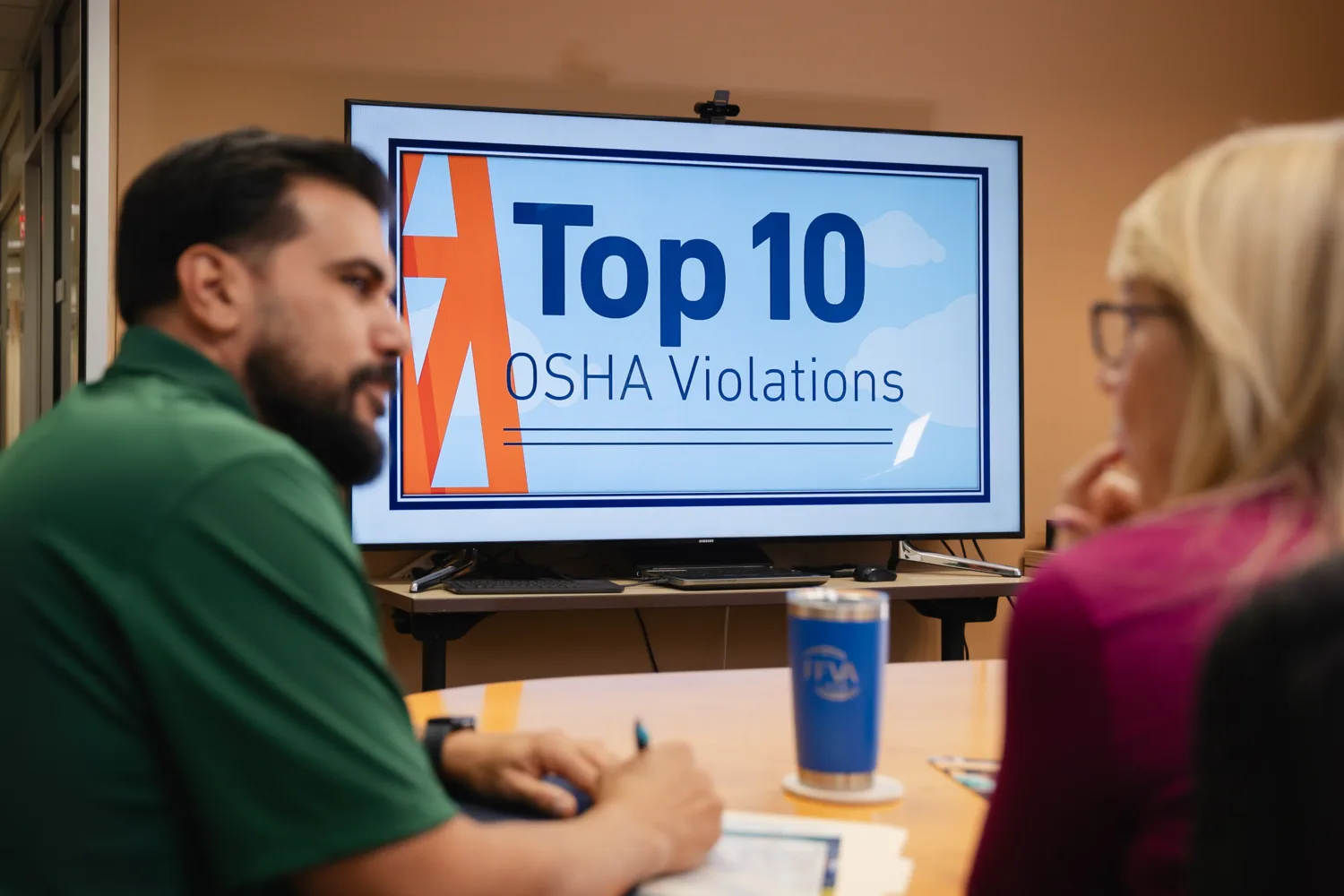

OSHA compliance requirements and FFVA Mutual’s forklift safety train the trainer course

Employers are required to follow the powered industrial truck guidelines detailed in OSHA’s 1910.178 standard, which covers safety requirements for 11 different types of trucks.

Additionally, the 1910.178 powered industrial truck standard also provides criteria regarding:

- Inspections

- Authorized operators

- Trainings

Fortunately for employers, the 1910.178 OSHA compliance standard is different from other standards because it is clear and to the point, making it significantly easier for employers to understand exactly what their obligations are.

In-house versus outsourced training

Rather than outsource training to a third party, some companies choose to hire an in-house trainer to manage all employee training sessions, including both operator safety training and refresher training, saving them time and money and creating more relevant safety programs for their employees.

OSHA requires that all in-house trainers understand the workplace hazards specific to the employers’ operations as well as know the ins and outs of all job-site equipment.

FFVA Mutual’s “train-the-trainer” approach

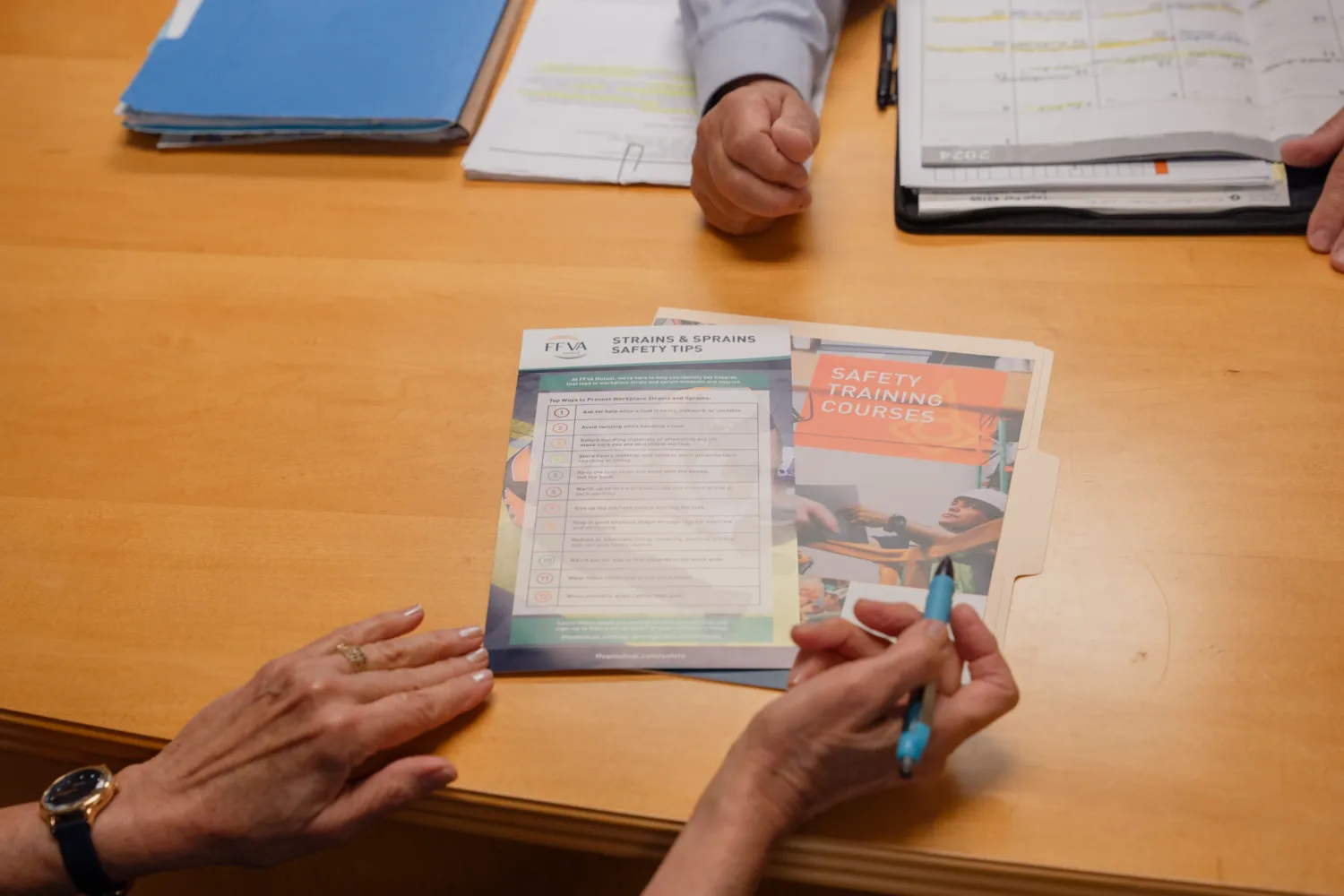

At FFVA Mutual, we offer a train-the-trainer safety program at no additional cost for our policyholders. Rather than providing safety training directly to forklift operators, we offer a program specifically for the designated in-house trainer, providing them with the essential safety information they need to manage their own training courses effectively, which they can tailor to fit the specific requirements of their workplace.

Our train-the-trainer course is available via:

- On-demand streaming

- In-person sessions

- Virtual training

Reach out to our team today if you’re interested in signing up for any of our safety training courses. If you want to learn more about our workers’ compensation insurance policies, get in touch with our team to start a conversation.