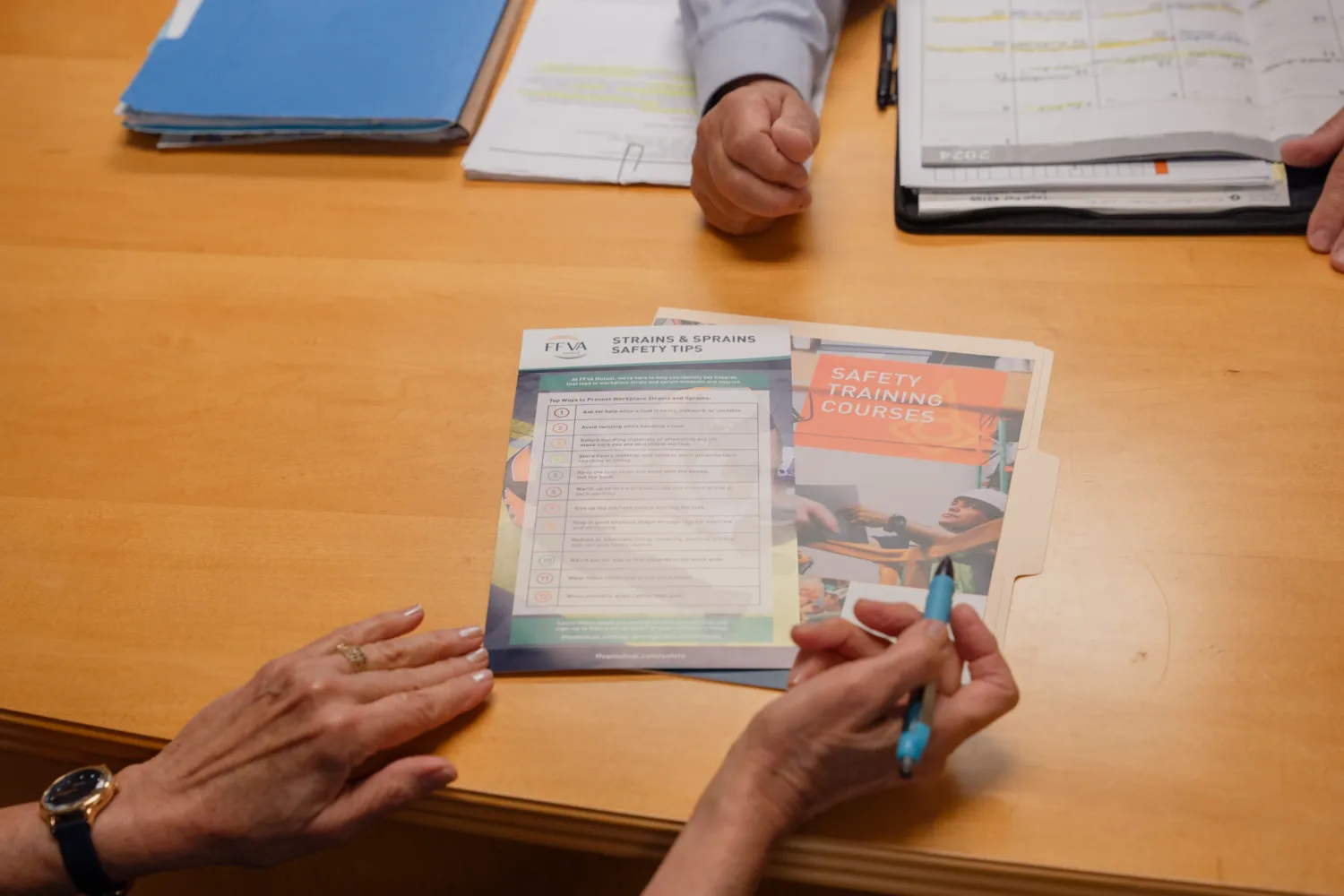

The surest way to protect your employees from avoidable accidents and injuries is to provide them with information and resources they need to stay safe at work, which is why FFVA Mutual offers workplace safety training courses on over 30 topics at no cost to our agents and policyholders.

According to the Institute for Work & Health, only 1 out of 5 new employees receive adequate safety training during their first three months on the job. However, new employees are not the only group of workers at risk. The truth is, safety training must be continuous to keep employees up to date with new rules, regulations and opportunities for improvement.

With so many training courses available, it can be challenging to pin down exactly what your workers can benefit from. To help you narrow down your options, we’ve put together a list of our top 5 safety training courses that every employer should consider:

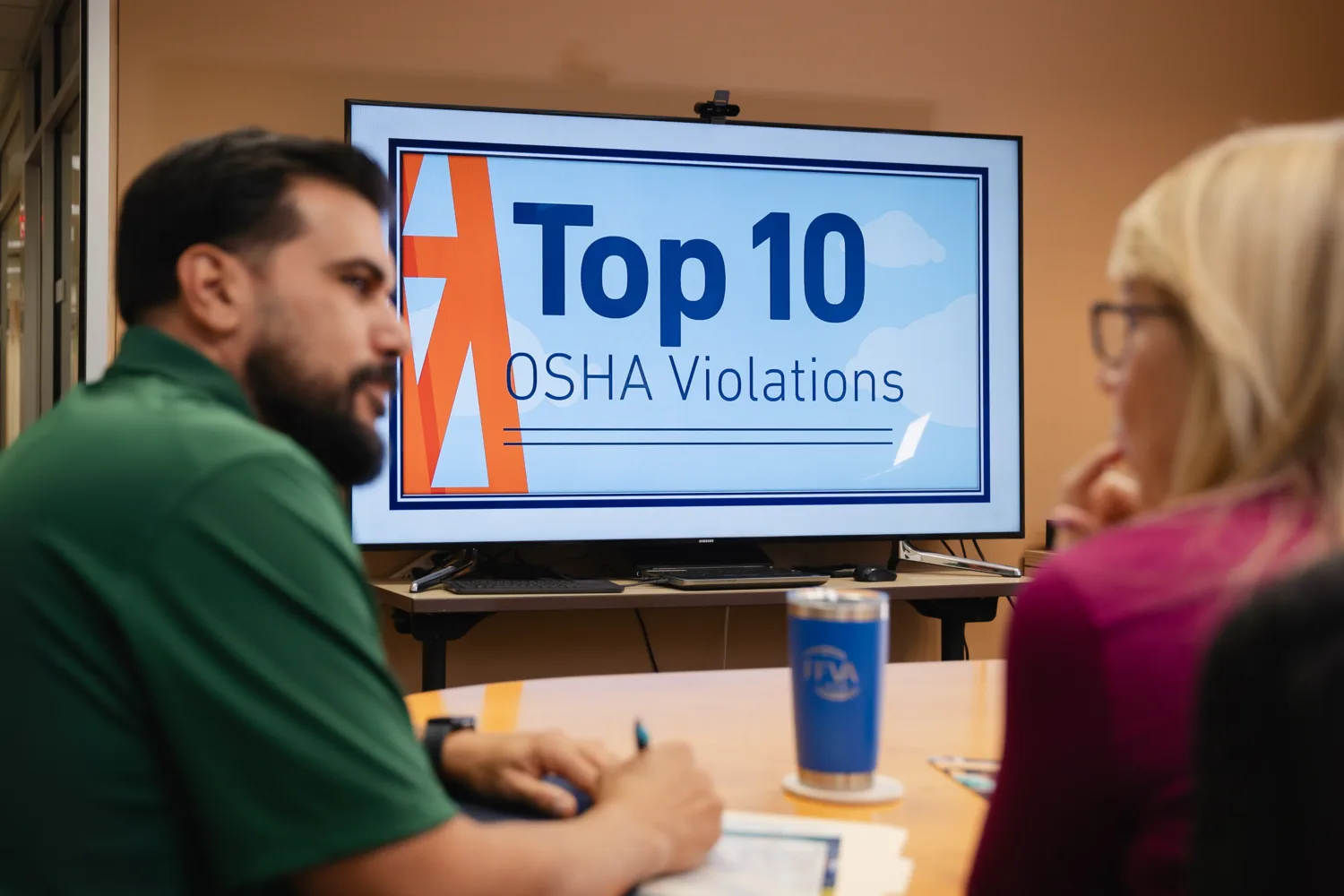

1. 10-Hour OSHA – General Industry

The Occupational Safety and Health Administration (OSHA) is a driving force in the world of workplace safety, as the agency is responsible for setting general standards and enforcing regulations. OSHA’s policies represent years of data-driven research that can significantly improve working conditions and keep your employees safe. OSHA training courses give employers and workers a better understanding of common safety hazards and ways to prevent injuries.

Key Takeaways:

- Overview of OSHA compliance

- Basics of hazard communication

- Best practices for electrical safety

- Personal protective equipment (PPE) standards

- Slips, trips and falls prevention

2. Safety Leadership

Safety management is all about informed leadership and open communication, making these types of training courses a valuable resource for employers. Promoting increased coordination among managers, supervisors, owners and safety professionals is the surest way to develop comprehensive strategies to improve workplace safety and reduce injury costs.

Key Takeaways:

- Easy-to-implement initiatives to help your bottom line

- Reducing workplace injuries through safety management

- Specific procedures for safeguarding workers on the job

- Tips for lowering claim costs following an injury

3. First Aid/CPR

When accidents happen at work, your employees are often the first on the scene. Preparing your workers to quickly respond to medical emergencies can save lives and may reduce the impact of serious injuries. According to the American Heart Association, performing CPR immediately following an incident of cardiac arrest can double, even triple, a person’s chance of survival. But less than 50 percent of people who experience cardiac arrest are given CPR assistance, in part due to the lack of general experience with the procedure. With that in mind, CPR and first aid training is a crucial measure for protecting your employees’ well-being when it matters most.

Key Takeaways:

- AED defibrillator training

- Detailed instruction on basic first aid procedures

- Emergency response preparedness

- First-hand experience with CPR

- Practice within work-related scenarios

4. Defensive Driving

Motor vehicle accidents stand as the leading cause of on-the-job fatalities, making defensive driving techniques a crucial part of an effective fleet safety program. The National Highway Traffic Safety Administration attributes around 95 percent of all crashes to driver error, which highlights the need for improved training guidelines for commercial drivers. Defensive driving courses can prepare your workers for all kinds of roadway hazards and teach them how to stay alert behind the wheel. Employers who enroll their drivers in these training programs benefit from reduced liabilities and injury costs – and more importantly, keep their employees safer on the road.

Key Takeaways:

- Defensive driving techniques

- How to reduce workplace auto accidents

- May decrease insurance costs and liability exposure

5. Forklift – Train the Trainer

Forklifts are an essential tool for most warehouse and industrial teams, as they provide an efficient and reliable method for moving around heavy boxes and equipment. However, OSHA estimates that nearly 100,000 workers are injured every year handling this machinery, with the majority of cases stemming from improper training and careless operation. Most businesses handle forklift training in-house, but who trains the trainers? On-site safety training helps ensure your employees are up to speed with the latest operational guidelines and provide your forklift training staff with the resources they need to instruct future employees.

Key Takeaways:

- Best practices for testing forklift proficiency

- Detailed advice for in-house forklift trainers

- Instruction on OSHA recordkeeping requirements

- Review of OSHA’s Standard (1910.178) on Powered Industrial Trucks

No matter which course(s) you select for your employees, safety training courses are a key component to a successful safety program at any workplace. If you’re interested in scheduling training for your employees, email us at safetytraining@ffvamutual.com. Also, be sure to check out our latest online and live events by visiting ffvamutual.com/events/.