The Importance of Ladder Safety

Improper ladder usage can be dangerous and lead to accidents, injuries or worse. Unfortunately, many employers either neglect the safety of this critical job function or simply don’t know how best to promote ladder safety.

The truth is ladder safety should be a priority for every employer and employee. The good news? Promoting safe ladder practices doesn’t have to be complex or time-consuming. A few simple, consistent safety measures can significantly reduce the risk of accidents and help keep your team safe on the job.

Common Causes of Ladder Accidents

Falls, instability and electrical shock are among the most common safety hazards associated with ladders, according to the National Ag Safety Database. There are several unsafe ways employees use ladders that could increase the likelihood of one of these incidents leading to accident or injury, including:

- Incorrect Ladder Angle: Approximately 40% of ladder-related injuries are due to setting up extension ladders at an improper angle, leading to base slides.

- Inappropriate Ladder Selection: Using a ladder that is too short, too long, or made of the wrong material for the task can result in instability and accidents.

- Insufficient Inspection: Failing to inspect ladders for damage or wear before use increases the risk of structural failure.

- Improper Use: Overreaching, carrying objects while climbing, and applying excessive force are common improper uses that lead to falls.

- Lack of Training: Many individuals lack access to proper ladder safety training and resources, contributing to misuse and accidents

Unsafe ladder practices can be extremely dangerous and possibly fatal. According to the U.S. Bureau of Labor Statistics, there were 22,710 workplace ladder injuries in 2020, and a total of 161 deaths. Industries with a focus on installation, maintenance, repair, construction and extraction accounted for nearly half of all ladder injuries.

More recently, in 2023, the BLS reported that portable ladders and stairs were the primary source of 109 fatalities in the construction industry—highlighting that the dangers remain very real and persistent.

9 on-the-job ladder safety best practices

There are several vital steps employees can take to stay safe on a day-to-day basis. Here are the nine most helpful ladder safety tips employees can practice every day:

- Maintain three points of contact: Make sure employees are following the three-points-of-contact rule. To ensure balance and stability, employees should keep three body parts—either two hands and one foot, or two feet and one hand—on the ladder at all times. This simple rule significantly reduces the risk of slips and falls.

- Face the Ladder When Climbing or Descending: Climbing while facing the ladder keeps the body aligned and secure. Employees should never turn their backs when ascending or descending, as this increases the risk of missteps and falls.

- Keep Loads Light When Climbing: Heavy or bulky items can throw off balance. Employees should avoid carrying tools or materials up and down ladders and instead use tool belts or have items handed to them by a coworker.

- Set Ladders on Solid, Level Ground: A ladder is only as safe as the surface it stands on. Always place it on firm, level ground like concrete, and never on soft, uneven surfaces that can shift or give way.

- Never Stack Items Under a Ladder: Using boxes, pallets, or other objects to extend ladder height is dangerous and unstable. If extra height is needed, opt for a taller ladder and consider assigning a spotter to stabilize the base.

- Use the Proper Angle for Extension Ladders: When setting up an extension ladder, follow the 4-to-1 rule: For every four feet of ladder height, place the base one foot away from the wall. This helps prevent the ladder from tipping or slipping.

- Inspect Ladders Before Every Use: Employees should thoroughly check ladders for cracks, bent rungs, or broken locks before climbing. Damaged ladders should be removed from service until they can be properly repaired or replaced.

- Choose the Right Ladder for the Job: Different jobs require different ladder types. Step ladders are ideal for low-height tasks, while extension ladders are best for reaching higher areas. Using the correct ladder helps ensure both safety and efficiency.

- Stay Clear of Electrical Hazards: When working near power lines or electrical sources, employees should use non-conductive ladders made of fiberglass or wood. Metal ladders can conduct electricity, posing serious electrocution risks.

5 Steps to Safer Ladder Use at Work

Of course, to promote better ladder safety across the entire organization, leadership needs to institute a culture of workplace safety. Here are some steps you can take to make ladder safety a priority in your organization:

- Assign a ladder leader: You should assign a designated ladder inspector who will conduct all daily inspections of ladders, looking for possible damage. This person should have extensive experience using ladders and should understand how each component functions properly.

- Invest in high-quality ladders: Investing in high-quality ladders is essential for promoting workplace ladder safety. High-quality ladders are built to withstand heavy use and are less likely to experience wear and tear over time. They’re also designed to provide superior stability and support, reducing the risk of falls and other accidents.

- Conduct a job hazard analysis: Workplace conditions might make ladder usage more dangerous. That might mean the prevalence of exposed electrical wires or excessively slippery floors. Conduct routine job hazard analyses to identify any possible workplace hazards and take steps to ensure safe and clean working conditions.

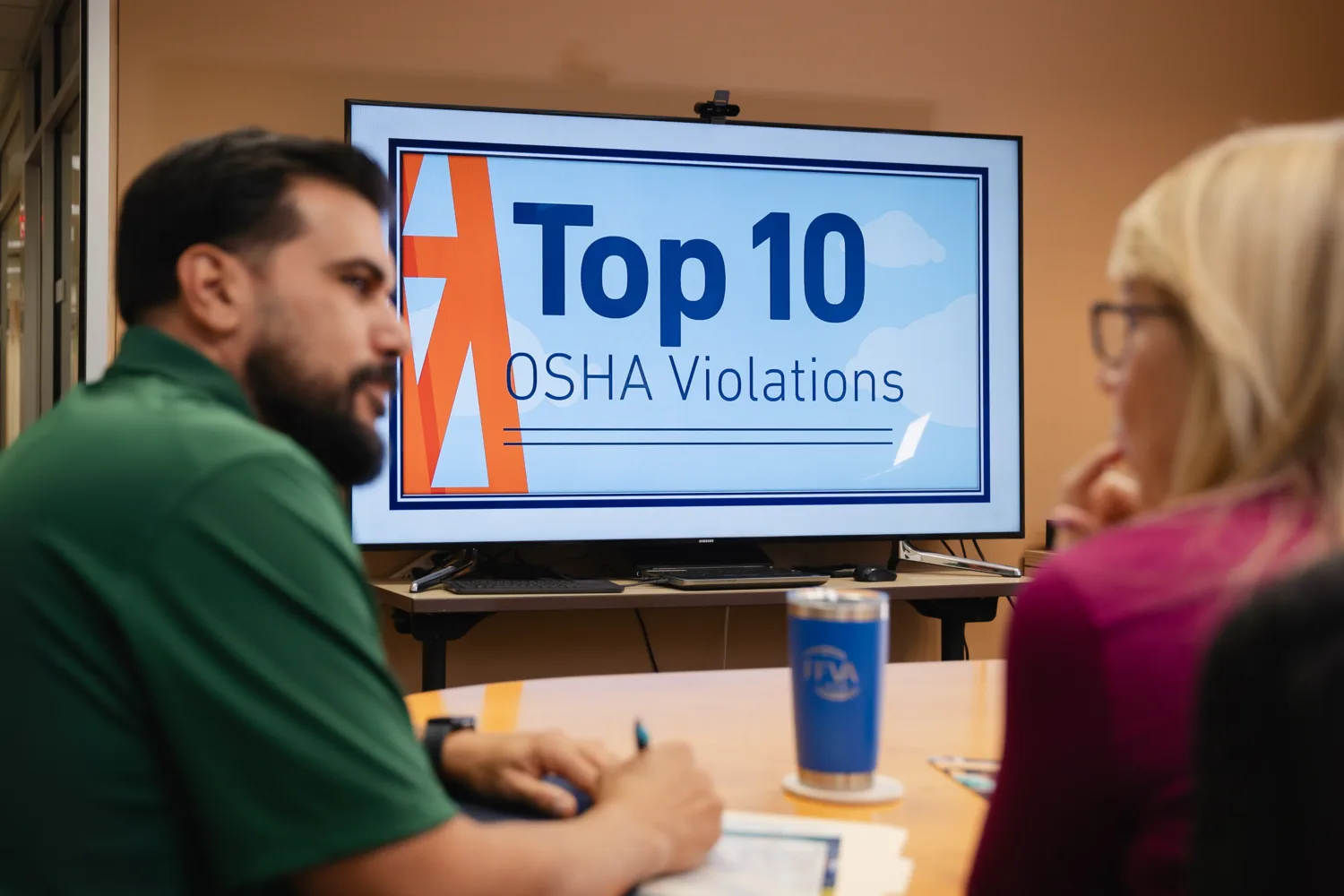

- Invest in employee training programs: Employee training is one of the most effective ways to prevent workplace ladder injury. Periodically train your employees on ladder safety best practices that are most relevant to your specific workplace requirement. All training programs should include experienced employees, who might still be willing to take dangerous shortcuts when using ladders.

- Establish a safety committee: Your safety committee serves as your organization’s dedicated group of safety-focused individuals. It’s responsible for prioritizing safety topics, earmarking funding for training and assigning individuals to specific safety-related roles. It should also play a lead role in all workplace-safety initiatives.

Ladder Safety Training with FFVA Mutual

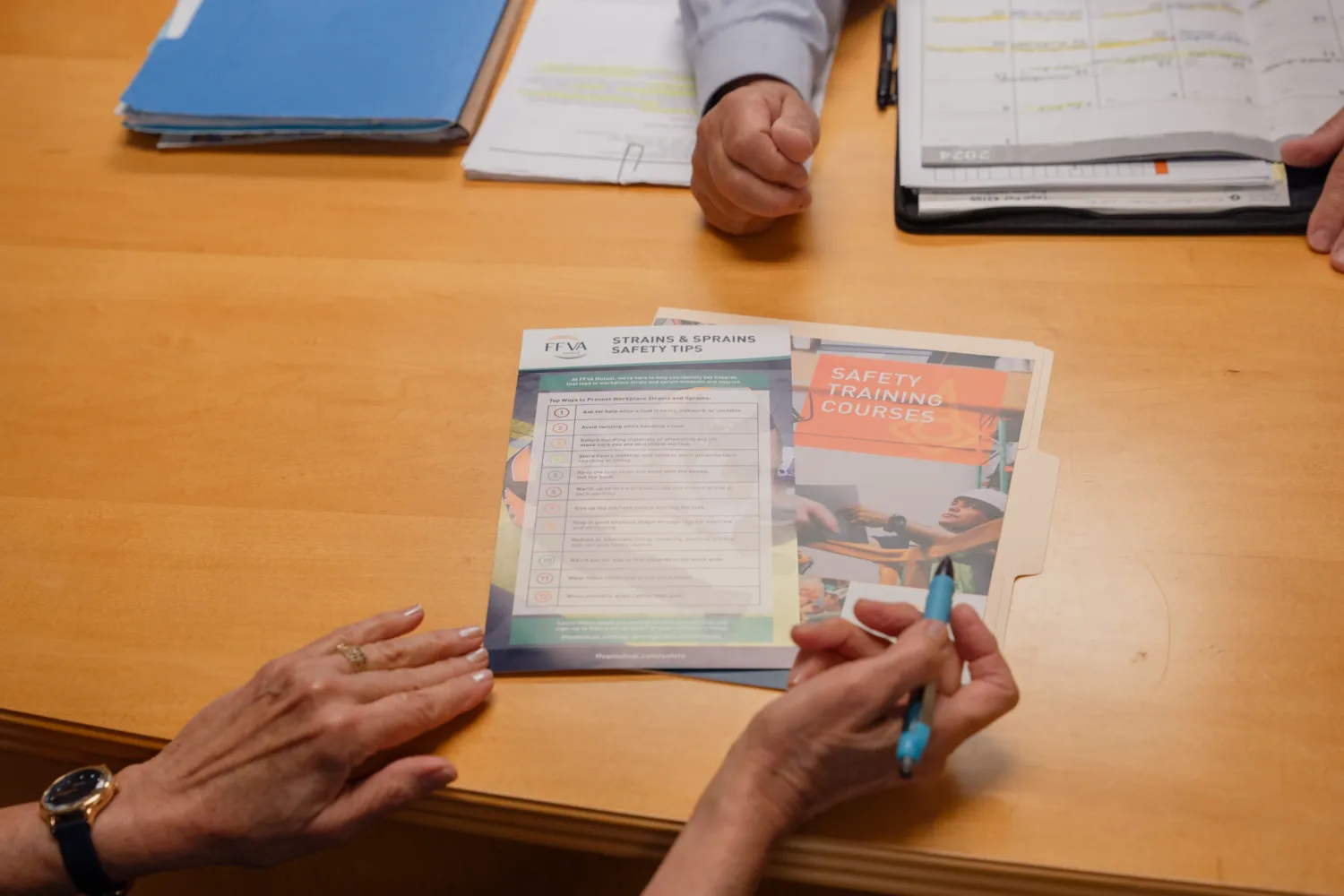

Creating a strong safety culture starts with the basics and ladder safety is one of them. At FFVA Mutual, we’re committed to helping our policyholders protect their employees through comprehensive safety training.

Our ladder safety courses provide essential guidance on topics including:

- Fixed ladders

- Portable ladders

- Proper ladder care and usage

- Safe ladder placement

- Routine ladder maintenance

- Choosing the right ladder for the job

- Participating in Ladder Safety Stand-Down events

We offer policyholders courses in a range of formats, including on-demand recordings, in-person sessions and virtual classes, giving them the convenience to access training information that fits their preferences. If you want to learn more about our safety training courses or if you’re ready to sign up for one, visit our safety training course page to get started.

Our workers’ compensation Solutionists at FFVA Mutual work closely with customers to deliver personalized underwriting, safety and claims services to help them improve workplace safety and resolve claims fast. Reach out to our team to get a conversation started