Create a Safer, Stronger Workplace

A safe workplace doesn’t happen by accident, which is why understanding safety tips for work is crucial. These 12 safety tips for work can help guide you in maintaining a secure environment. It’s the result of clear protocols, consistent training and leadership that takes safety seriously. For employers, that means more than just checking a box. It means recognizing potential hazards before they lead to incidents and making safety part of every shift, every task and every worker’s routine.

As workplace risks evolve, so should your safety strategy. From outdated equipment to overlooked hazards, even small oversights can lead to a serious workplace injury. That’s why it’s critical to take a proactive approach rooted in awareness, consistency and clear communication.

We’ve compiled 12 essential safety tips drawn from real-world job sites, FFVA Mutual’s safety expertise and industry best practices.

12 Safety Tips for Work Every Employer Should Implement

Whether you manage a construction crew, operate a manufacturing line or oversee an administrative facility, these 12 strategies will help you maintain a safe workplace and minimize the risk of a workplace accident.

1. Report Unsafe Conditions Immediately

Under the Occupational Safety and Health (OSH) Act, employers have a responsibility to provide a hazard-free workplace and to address known safety risks. A small leak, exposed wire or unstable platform may not seem urgent — but left unreported, it becomes a liability.

Encourage employees to identify and report unsafe conditions before they escalate. Offer simple reporting channels, like mobile apps or paper forms, and make it clear that raising a safety concern is not only welcome but expected. Consider anonymous submission options and train supervisors to act quickly and transparently.

2. Keep a Clean and Organized Workstation

Disorder invites injury. Spills, debris, tangled cords and misplaced tools increase the risk of tripping, slipping and even fire. Whether it’s around an assembly line, tool bench or desk, maintaining order is a basic yet critical part of workplace safety — and meeting Occupational Safety and Health Administration (OSHA) requirements for walking working surfaces. Regularly scheduled cleanups, labeled storage systems and clear walkways help minimize the chance of injury. In an industrial setting or an office environment, cleanliness is a universal safety practice.

3. Be Aware of Your Surroundings

Situational awareness is often the first defense against workplace injury. Train employees to stay alert, read posted safety guidelines and recognize common hazards specific to their roles. This includes proximity to machinery, spills, sharp edges or hazardous materials. Remind everyone that a few seconds of attention can prevent long-term consequences. Awareness also extends to coworkers; looking out for each other is part of a strong safety culture.

4. Never Take Shortcuts on Safety

Rushed decisions are a common cause of workplace accidents. Skipping steps to save time may seem harmless in the moment, but over time it erodes compliance, increases exposure to hazards and sets a dangerous precedent for new workers.

Reinforce the importance of following safety procedures exactly as trained. This includes using the right tools, wearing proper protective gear and completing each task according to established safety standards. Shortcuts might feel efficient, but they often lead to avoidable injury and disruption.

5. Wear Personal Protective Equipment

The right personal protective equipment (PPE) helps prevent serious injury. Hard hats reduce impact from overhead objects. Safety goggles shield against flying debris and chemical splashes. Gloves, ear protection and steel-toed boots each serve a distinct purpose depending on the environment.

OSHA requires employers to provide task-specific PPE, train workers to use it and ensure it fits properly. It’s also a good idea to stock backup equipment. If PPE is worn inconsistently or without understanding, it can create a false sense of security and an increased safety risk.

6. Inspect and Maintain Emergency Equipment

Preparedness isn’t just about having the right gear — it’s about making sure it works and that your team knows how to use it. In an emergency, untested or unfamiliar safety equipment can turn a minor incident into a major event.

Conduct regular inspections of fire extinguishers, eyewash stations, defibrillators and alarm systems. Verify that emergency procedures are posted clearly and understood by all workers. Include emergency response drills in your routine safety training to build muscle memory and reduce confusion in real-time situations.

7. Follow Established Safety Protocols

Every job site needs clear, repeatable safety protocols that guide behavior during routine and high-risk tasks. Post safety rules where workers can see them. Use visual cues in shared spaces, like signage for chemical zones or restricted areas, and verify that standard operating procedures (SOPs) are up to date. Whether employees are working near machinery or handling hazardous material, consistency protects everyone.

8. Understand the Hazards in Your Specific Workplace

No two job sites are the same. An effective safety program starts with identifying the specific workplace hazards your team faces. This includes chemical exposure, excessive noise, poor workplace ergonomics, fall risks and repetitive motion injuries.

Walk through each work area and involve employees in the hazard assessment process. Workers often spot issues that leadership may overlook. Encourage employees to report minor issues without fear of blame or penalty. Use these findings to inform task-specific safety measures, signage and targeted safety training. The better you understand your risks, the more precise your prevention efforts will be.

9. Practice First Aid Readiness

When a workplace incident happens, response time matters. Every facility must have well-stocked first aid kits in easily accessible locations. These kits should be inspected regularly and include essentials like bandages, antiseptics and burn treatments.

Beyond equipment, OSHA strongly advises CPR certification and basic first aid training for key team members. Periodic emergency procedure drills reinforce readiness and give workers the confidence to act fast.

10. Track Incidents and Near Misses

A single near miss is a warning, but patterns of them reveal deeper problems. Use incident logs to monitor both injuries and close calls. Track when, where and how events occur to spot trends and address root causes. Not only is data required by OSHA record-keeping rules, but it will also guide smarter safety policies, reveal gaps in safety practices, and help prevent the next serious workplace injury before it happens.

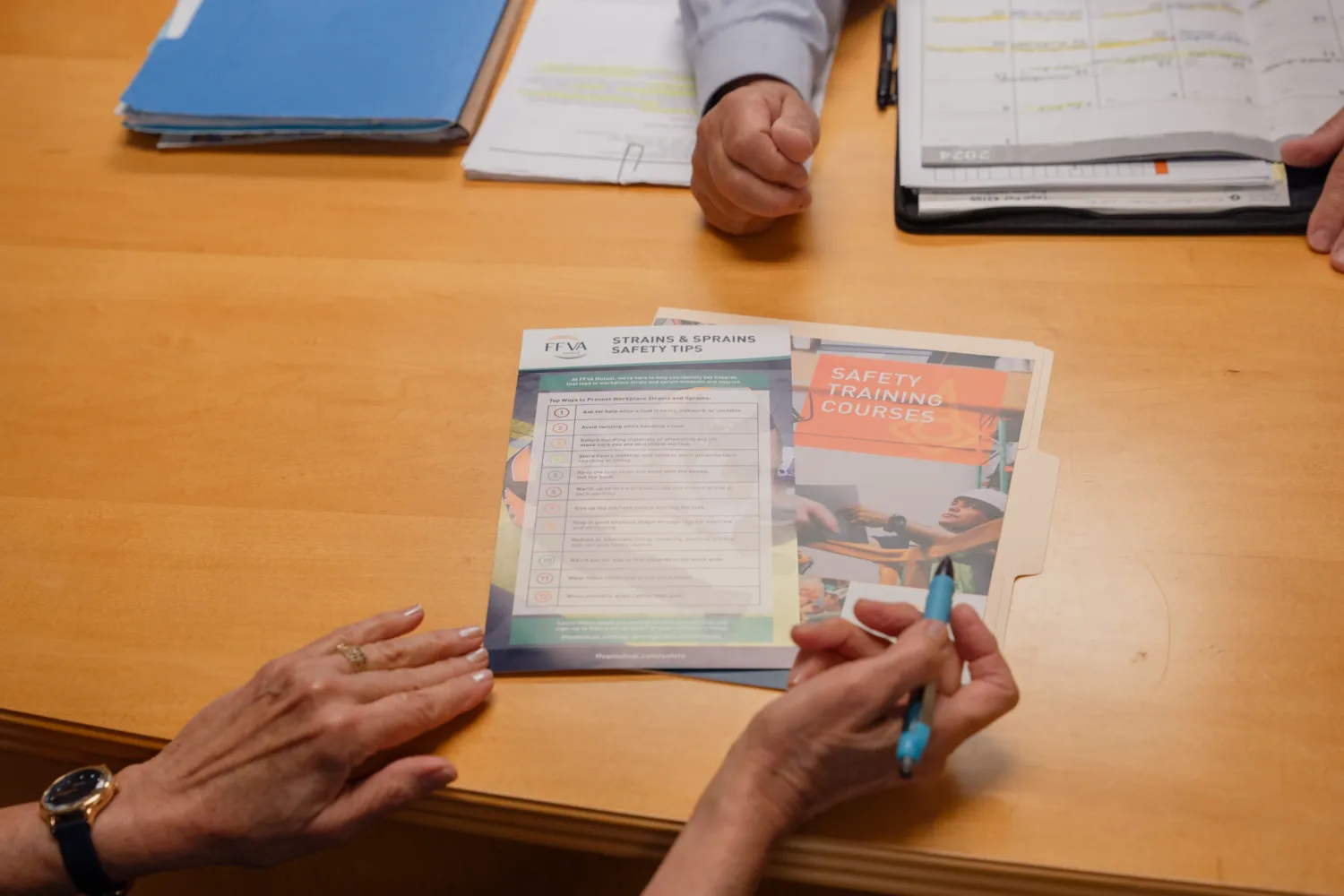

11. Provide Continuous Safety Training

A one-time course doesn’t build a safe working environment. Safety must be a constant part of your workplace culture. Integrate safety training into onboarding, team meetings and job-specific refreshers. Focus on real-world scenarios and the lessons learned from past workplace incidents. Rotate topics so training stays relevant. Include discussions on proper lifting techniques, emergency protocols and new safety equipment as it’s introduced. Reinforcement keeps good habits from slipping.

12. Promote a Speak-Up Culture

All of these workplace safety tips are worthless if employees are afraid to use their voices. Build a culture where workers feel supported when they raise concerns. Supervisors should respond to reports without judgment and follow up with clear next steps. Consider anonymous options for reporting unsafe conditions or broken safety protocols. A workplace where employees speak up is one where injuries are less likely to happen. Listening is one of the most powerful tools for preventing harm.

How To Maintain a Culture of Continuous Safety Improvement

A true safety culture requires constant attention, especially as teams grow, equipment evolves and work environments change. To build a safer workplace, leadership must stay engaged. Regular safety audits, walk-throughs and informal check-ins are essential for spotting new risks before they escalate.

Use digital tools to log observations, track open issues and analyze trends over time. Dashboards, mobile checklists and audit tools offer real-time insight into how well your current safety standards are being followed. Make sure your reporting systems are accessible and that employees feel confident using them.

Most importantly, treat every employee as a stakeholder in your safety program. Recognize safe behaviors publicly, respond to reports quickly and adjust workplace safety procedures as needed. When safety is visible, valued and constantly reinforced, it becomes part of how work gets done.

Build a Safer Future with FFVA Mutual

At FFVA Mutual, we help employers strengthen their safety strategies with expert insights, practical tools and personalized guidance.

If you’re reviewing your safety protocols, updating your training program or trying to reduce workplace injuries, our team is here to help.

Ask a Safety Question and start building a safer, stronger workplace today.