Discover Proactive Safety Measures

A workplace safety program is a structured approach to identifying, managing, and reducing risks in the workplace. An effective program protects employees, boosts engagement, and supports regulatory compliance.

No matter what business you’re in, a strong foundation for success should include an effective workplace safety program that delivers long-term value. A written program—accessible to every worker—is a win-win for employers and employees alike. For employers, it increases productivity, improves engagement, and reduces absenteeism. For employees, safety training and education foster a sense of support and empowerment.

So, what makes a safety program successful? While organizations like the Occupational Safety and Health Administration (OSHA) offer many helpful resources, every effective workplace safety program shares three essential traits: it prevents injuries, communicates procedures clearly, and builds a lasting culture of safety.

1. Prevents Injuries

The best workplace health and safety program is one that keeps employees from getting injured to start! As OSHA points out, nearly all workplace incidents, injuries, and even fatalities are preventable.

Preventive measures, when clearly communicated, help prevent incidents and injuries. For example, you can:

- Reduce the likelihood of slips, trips and falls by providing personal protection equipment (PPE) and offering employee safety training and resources that reinforce best practices.

- Develop hazard communications to highlight specific potential hazards workers may encounter.

- Implement workplace wellness programs. Happy and healthy employees are less likely to experience a workplace injury.

- Perform regular workplace inspections and job hazard analyses (JHA) to identify existing hazards and any potential risks.

Preventive measures, including the use of PPE, reduce the chance of worker injury.

In addition to preventing workplace injuries, having an effective workplace safety programs also reduces overall claim costs. According to the National Safety Council, the total cost of work injuries in the U.S. reached $167 billion in 2022, underscoring the financial value of an effective safety program.

2. Communicates Procedures

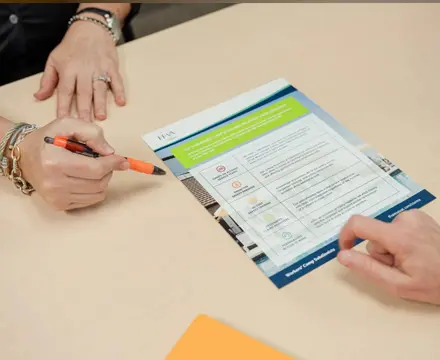

Providing clear and consistent communication ensures employees know what to expect and what to do to stay safe on the job. Most health and safety programs include written policies, processes and procedures that outline safety requirements for employees to follow.

Here are examples of the most common workplace safety programs:

- Emergency Action Plan

- Fall Protection

- Job Hazard Analysis Plan

- General Safety and Health Program

- Hand and Power Tools

- Ladder Safety

- Lockout/Tagout

- Machine Safeguarding

- Personal Protective Equipment (PPE)

- Return to Work

Walkthroughs, checklists and reviewing loss trends can help you uncover trouble spots before they lead to injuries. Ask employees to point out any issues that may be overlooked. According to OSHA’s most recent data, the most cited workplace violations include fall protection, hazard communication, and lockout/tagout procedures—highlighting the importance of regularly assessing these types of risks.

When a hazard or injury crops up, having clearly communicated steps in place reassures employees that your company is invested in safety and the well-being of every worker. Simple, yet powerful communication tools boost morale and gives workers confidence knowing that they’re in good hands.

Looking for templates or safety forms?

Check out FFVA Mutual’s Safety Key Toolkit for downloadable checklists, inspection forms, and policy starters designed for employers.

3. Creates a Safety Culture

While safety ultimately starts at the top, it’s important that business owners, managers and workplace safety committees collaborate to demonstrate the benefits of a safety program. Bringing in a safety committee and other employee representatives gives workers a voice in maintaining a safe work environment.

At the end of the day, the success of a safety program comes down to one thing: Support that everyone buys into. You could have the most comprehensive safety program in place, but if employees are not educated, motivated or inspired, it will not be an effective safety tool.

Tracking and Monitoring Success

So, after you’ve established a solid safety program that focuses on preventing injuries, communicating procedures and fostering a safety culture, you need to stop and think: How do you measure its effectiveness?

Simple — by paying attention to various key performance indicators (KPIs) and other metrics, you’ll gain valuable insights into what’s working and what needs fine-tuning. Start by tracking and monitoring the following:

- Injury frequency rate: Measures the rate of injuries per 100,000 hours worked.

- Average duration of incidents: Monitors how long it takes for normal operations to resume following an incident.

- Safety training completion rate: Keeps tabs on the percentage of employees who have completed safety training modules.

Additionally, here are some more metrics you can measure over time:

Incident rates

Incident rates offer a straightforward way to quantify how safe or unsafe your work environment is. Comparing these rates can show trends, enabling proactive measures before small problems snowball into major issues.

Reported incidents

Actively encouraging your workforce to report safety incidents, such as slips, trips and falls (even those that seem minor), establishes an environment of shared responsibility. The more data you have, the better your insights into areas that require immediate attention.

Equipment breakdowns

If machinery frequently breaks down despite regular maintenance, this can indicate a deeper, systemic issue that poses safety risks. Equipment breakdown metrics can provide a crucial early warning system for underlying safety issues.

Attendance to workshops/talks

The more employees participate in safety workshops and talks, the better the program’s reach and, by extension, its effectiveness. If attendance is low, it could be a sign that the program is not resonating with your workforce or that the topics covered are not seen as relevant.

Employee-driven safety initiatives

Employee engagement in safety is a strong indicator of a program’s success. Track the number of employee-led safety initiatives, such as suggestions for improvements or safety workshops. This not only provides another layer of safety but also makes employees feel valued and heard.

Creating a Culture of Safety

A strong safety culture starts at the top. Leaders set the tone for the entire organization, and when they prioritize safety, employees are more likely to follow suit. This means more than just talking about safety—it requires action. Executives, managers, and supervisors should actively participate in safety training, adhere to protocols, and demonstrate a commitment to workplace well-being. When leadership consistently models safe behaviors, it reinforces their importance and encourages employees to do the same.

Clear and open communication channels are the arteries of this safety culture. Got a malfunctioning piece of equipment or a bright idea to make the job site safer? Everyone should feel free to speak up. Turn to digital platforms, safety bulletins and internal newsletters as your go-to channels for keeping everyone in the loop.

That said, culture isn’t solely built on communication and ownership — it thrives on recognition and rewards. When the members of your team see their hard work in the safety department getting some love, guess what? They’re going to keep at it! Of course, the flip side of recognition is accountability. Holding everyone accountable for their actions and implementing consistent consequences for safety breaches sends a clear message about your organization’s values.

Learning and adaptation are also pivotal. After all, the world doesn’t stand still, and neither should your approach to safety. Take the data and insights gleaned from tracking and use them to update safety protocols, tools and training. Make training an ongoing process, seamlessly integrated into your operational flow. New hires should be immersed in safety culture from day one, and veteran employees should see safety as a continuous learning journey. To help you get going, here are some workplace safety topics to discuss in meetings. The National Safety Council (NSC) also offers safety topic insights.

External validation, coming through processes like periodic audits from third-party organizations, provides another layer of credibility and offers an impartial view of your safety measures. It’s an excellent way to identify blind spots and areas that could benefit from improvements.

Frequently Asked Questions About Workplace Safety Programs

Q1: What is the purpose of a workplace safety program?

A workplace safety program helps identify and control risks to prevent injuries, lower claims, and foster a proactive safety culture.

Q2: How do I start an effective workplace safety program?

Start with leadership commitment, assess workplace risks, set clear goals, and involve employees from day one. Training and evaluation are key.

Q3: How often should a workplace safety program be reviewed?

At least annually, or after any major incident. Regular reviews keep the program effective, aligned with changing regulations and workplace needs.

Additional Resources from FFVA Mutual

If you’re searching for guidance on workplace safety or have specific questions, we’re here to assist. Are you keen on developing an effective workplace safety program that delivers tangible benefits? Our resource library, Safety Key, offers invaluable tools to get you started. For our policyholders, we provide a customizable Safety Program Guide template that you can customize to fit your specific workplace needs.

Need help launching an effective workplace safety program?

FFVA Mutual policyholders get access to expert consultation, training resources, and ongoing support. Contact a Safety Solutionist today to get started.