Tips and Resources for your Safety Program

Safe + Sound Week is OSHA’s annual August campaign that highlights the importance of workplace health and safety programs. It encourages businesses to promote hazard awareness, employee wellness, and a strong safety culture.

Each year, OSHA recognizes organizations that have successfully implemented effective safety programs through this week-long national event. Safe + Sound Week promotes innovation in hazard prevention and encourages employers of all sizes to host activities that engage workers and demonstrate a long-term commitment to safety.

Comprehensive and compassionate health and safety programs help employers in many ways, including:

- Demonstrating corporate social responsibility and workplace safety goals

- Engaging workers

- Improving regulatory compliance

- Increasing productivity and enhancing business operations

- Preventing workplace accidents, injuries and illnesses

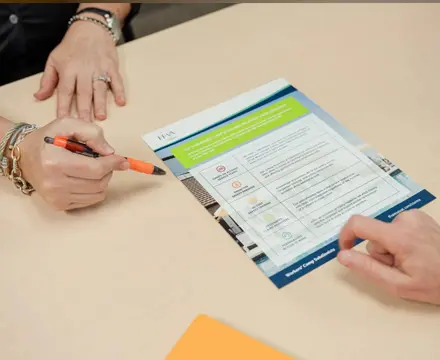

- Reducing costs and potentially also workers’ compensation premiums

To help businesses prepare for OSHA’s Safe and Sound Week, let’s take a closer look at what makes a health and safety program successful.

Benefits of OSHA’s Safe and Sound Week – Why Participate?

OSHA’s Safe and Sound Week is more than a reminder of workplace safety. It serves as a catalyst for developing and maintaining a strong safety culture. Participating in this event brings several benefits:

- Enhanced Safety Culture: Engaging in this annual event helps reinforce the importance of safety and health throughout your organization. This event fosters a culture where safety is prioritized and integrated into everyday practices. This proactive approach helps in preventing accidents and encourages employees to participate in safety initiatives.

- Boost in Employee Morale and Engagement: When employees see their organization taking steps to improve safety, it boosts their confidence in the workplace. Recognizing their contributions to safety efforts and providing a safer work environment leads to higher job satisfaction and motivation. Employees who feel safe and valued are more engaged and productive, contributing to a positive overall work atmosphere.

- Regulatory Compliance with OSHA Standards: Participating in OSHA’s Safe and Sound Week ensures your organization adheres to OSHA regulations, minimizing the risk of fines and penalties. By focusing on safety protocols and conducting thorough reviews, you can identify and address compliance gaps before they escalate. This proactive approach demonstrates your commitment to regulatory adherence and workplace safety.

- Productivity Boost: A safer workplace directly leads to fewer accidents and reduced downtime, enhancing overall productivity. By participating in Safe and Sound Week, you’re investing in safety and the efficiency of your operations.

3 Elements of Effective Health and Safety Programs

When it comes to building a successful health and safety program, OSHA identifies 3 core components that every employer should prioritize: management leadership, worker participation and finding and fixing workplace hazards. By incorporating these elements, businesses can ensure their policies and procedures are proactive, compassionate and in line with current best practices. Since open communication is also essential to combating on-the-job injuries and illnesses, it’s important for employers to focus on building productive relationships among business leaders, management teams and workers. To get an idea of how health and safety programs operate, let’s take a closer look at the specific elements that most often contribute to their success:

1. Management Leadership is Key to Safety Success

One of the most important components of a successful health and safety program is the direct involvement of C-suite executives and high-level managers, as these professionals have the authority and expertise needed to allocate resources and guide policy improvements. When business leaders are actively engaged in reducing workplace accidents, it demonstrates a genuine commitment to employee well-being and communicates that each worker is a valuable part of their organization. Some of the ways top management can actively support health and safety programs include:

- Creating policy statements and outlining workplace safety initiatives

- Developing clear implementation and performance goals for new programs

- Making health and safety part of their daily conversations and operational planning

- Acknowledging worker contributions and achievements

2. Encourage Worker Participation

While top-level support is essential to building an effective health and safety program, it’s also important to emphasize the value of employee insight and engagement. Workers often have firsthand experience with the specific hazards their employers are trying to mitigate, which enables them to make informed recommendations for improving existing policies. Fostering a collaborative environment and open dialog can also encourage employees to think critically about accident prevention and contribute their ideas during the planning and revision phases. Additionally, direct worker involvement can help employers find actionable solutions to some of the toughest health and safety challenges, promote awareness and cultivate productive relationships. A successful safety program is one that makes employees feel invested and appreciated, which is why every worker must be able to share their insight without fear of retaliation. Here are some of the common ways employees actively participate in their companies’ safety committees and programs:

- Assisting management with the development of accident prevention policies

- Identifying opportunities for improving routine and non-routine safety processes

- Performing weekly on-site inspections and incident investigations

- Training employees and new hires on safe work practices

3. Identify and Correct Workplace Hazards

In the past, many employers relied on a reactive approach to workplace safety that prioritized incident response and post-accident investigation. While this approach helps businesses improve their internal policies and procedures, it may leave them unprepared for major injuries that could significantly impact operational efficiencies. Modern health and safety programs place considerable emphasis on identifying and controlling workplace hazards through proactive and systematic processes. Rather than waiting for an accident, annual inspection or new piece of legislation, today’s safety-conscious employers focus on injury and illness prevention by making incremental improvements and regularly updating their training resources. The defining features of a systematic find-and-fix approach include:

- Reviewing workplace hazards when new information is made available

- Investigating on-the-job accidents to locate root causes and possible solutions

- Conducting regular inspections to identify emerging risks to employee health and safety

- Verifying the efficacy of existing programs and procedures

How to Participate in Safe + Sound Week

Participating in Safe + Sound Week can be both informative and engaging for safety managers and employees. Here are some activities to consider that demonstrate your organization’s commitment to workplace safety:

- Safety Short Talks – Hold daily or weekly short talks to address specific hazards and reinforce safety practices. For ideas and insights, visit our Safety Videos and Short Talks page.

- Safety Audits – Conduct comprehensive audits to identify risks, safety gaps, or improvement opportunities.

- Training Sessions – Organize sessions focused on critical topics such as fall protection, hazard communication, or emergency response—tailored to your industry.

- Safety Drills – Practice fire, weather, or chemical spill drills to ensure all team members know how to respond quickly and effectively. This helps ensure everyone knows what to do so your company is prepared for an emergency.

- Incentive and Recognition Programs – OSHA encourages incentive and reward programs to promote workplace safety. Recognize employees who contribute to a safer workplace through proactive behavior or hazard reporting.

You can also create custom events and awareness campaigns:

- Launch a wellness initiative – Support employee wellness through hydration stations, stretch breaks, or mindfulness sessions.

- Recognize safety champions – Highlight employees who demonstrate leadership in safety efforts.

- Share safety tips – Use email, posters, or digital signage to distribute daily safety messages.

- Partner with FFVA Mutual – Leverage your access to tools like the Safety Toolkit or attend our Safety Leadership Academy to strengthen your efforts.

OSHA also encourages employers to participate in Safety Challenges, which include activities aligned with three core pillars of safety: management leadership, worker participation, and finding and fixing hazards. Learn more about OSHA’s Safe + Sound Activities and Challenges.

Ways to Promote Safe and Sound Week

To maximize the impact of Safe and Sound Week for your workplace, promote your participation through various channels:

- Internal Communications: Use newsletters, emails, and postings in breakrooms to keep employees informed.

- Social Media: Share your safety activities on social media platforms using hashtags like #SafeAndSoundWeek and #OSHASafeAndSound.

- Community Engagement: Involve the local community and other businesses to spread awareness about workplace safety.

OSHA has many resources on their plan and promote your participation page on their website that includes a Step-by-Step Guide, customized printable sheets, social media graphics and more for your company!

Get Started Today! Customizing Safety Week to Fit Your Organization

Safe and Sound Week is an excellent opportunity to build an effective safety program and demonstrate your commitment to a safe and healthy work environment. By focusing on management leadership, employee participation, hazard identification, and ongoing training, you can build a robust safety program that benefits everyone.

Frequently Asked Questions About Safe + Sound Week

Q1: What is OSHA’s Safe + Sound Week?

OSHA’s Safe + Sound Week is a national event held each year to recognize the successes of workplace health and safety programs and offer information and ideas on how to keep America’s workers safe. It encourages businesses of all sizes and industries to focus on core safety principles like hazard awareness, employee engagement, and proactive planning to prevent injuries and illnesses on the job.

Q2: How can businesses participate in Safe + Sound Week?

Participation is flexible and easy. Employers can get involved by hosting safety talks, conducting walkthroughs or hazard assessments, promoting employee feedback on safety issues, or sharing success stories. OSHA also provides downloadable toolkits, posters, checklists, and planning guides to help organizations tailor the week’s activities to their unique needs.

Q3: What are the benefits of having a workplace safety program?

A well-structured safety program helps reduce injuries, improve morale, enhance compliance, and lower costs related to workers’ compensation claims and lost productivity. It also fosters a culture where employees feel valued and empowered to take an active role in maintaining a safe working environment.

Ready to strengthen your safety culture?

Sign up with OSHA’s Safe + Sound Week to take the first step toward a safer, healthier workplace. Whether you’re just starting your safety program or looking to enhance what’s already in place, Safe + Sound Week offers flexible ways to get involved.

Looking for effective training solutions?

FFVA Mutual provides no-cost safety training courses designed to help employers protect their teams, reduce risks, and foster long-term success. Explore FFVA Mutual’s safety no-cost training courses.